1. Golden Gate Bridge (San Francisco, USA)

Type: Suspension bridge

Construction Insights:

Designed by engineer Joseph Strauss with assistance from Leon Moisseiff and Charles Alton Ellis.

The bridge’s massive steel cables, manufactured by Roebling’s company, contain 80,000 miles of wire.

The construction faced challenges due to high winds, fog, and dangerous currents in the Golden Gate Strait.

A safety net was installed beneath the bridge to protect workers, saving the lives of 19 men (known as the “Halfway to Hell Club”).

The Art Deco design is a blend of functionality and aesthetics, with the famous “International Orange” color chosen for visibility against the fog.

2. Tower Bridge (London, UK)

Type: Bascule and suspension bridge

Construction Insights:

Designed by Sir Horace Jones in collaboration with civil engineer Sir John Wolfe Barry.

The bascule mechanism allows the bridge to open for ships to pass, using counterweights to minimize energy requirements.

Over 11,000 tons of steel were used in the framework, which is clad in Cornish granite and Portland stone to enhance its appearance and protect it from weather.

Originally powered by steam-driven hydraulic pumps, it now uses an electro-hydraulic system.

Construction took 8 years, employing 432 workers and overcoming issues with the foundation in the soft riverbed of the Thames.

3. Sydney Harbour Bridge (Sydney, Australia)

Type: Arch bridge

Construction Insights:

Engineered by J.J.C. Bradfield and built by Dorman Long, a British firm.

The construction required the temporary use of creeper cranes, which worked from both ends of the arch, meeting in the middle.

The granite pylons are decorative and do not support the structure.

Workers drilled and riveted approximately 52,800 tons of steel during construction.

The foundations for the pylons were built using caissons, which were sunk into the harbor floor.

During its construction, a total of 16 workers tragically lost their lives due to the high risks involved.

4. Millau Viaduct (Millau, France)

Type: Cable-stayed bridge

Construction Insights:

The deck was assembled in sections and launched longitudinally from both ends using hydraulic jacks.

The bridge deck is a steel box girder that was pushed out in segments across the pylons, minimizing environmental impact on the valley below.

The pylons were cast using climbing formwork and supported by deep foundations anchored in limestone rock.

Special wind tunnels were used during the design phase to test the bridge’s resistance to strong winds.

Despite its height, the bridge offers remarkable stability due to its streamlined profile and state-of-the-art engineering.

5. Brooklyn Bridge (New York City, USA)

Type: Suspension/cable-stayed hybrid bridge

Construction Insights:

Designed by John A. Roebling, but completed by his son, Washington Roebling, after John’s death.

The construction used massive pneumatic caissons for the foundation, sunk into the riverbed. Workers faced extreme conditions and decompression sickness.

The bridge was the first to use steel for its cable wires, which significantly enhanced its strength.

Over 600 workers were involved in its construction, enduring extreme weather and the challenges of working over the East River.

At the time of its opening, it was the longest suspension bridge in the world, and it has since become a symbol of New York City.

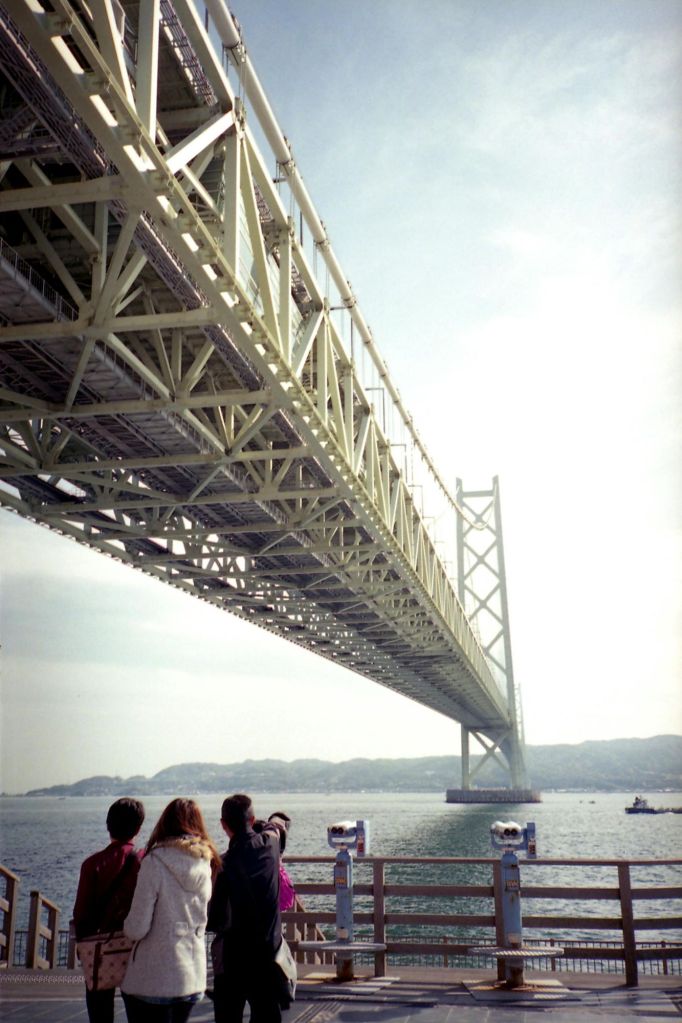

6. Akashi Kaikyo Bridge (Kobe, Japan)

Type: Suspension bridge

Construction Insights:

Designed to withstand earthquakes and typhoons, including the 1995 Kobe earthquake, which shifted one of the towers by nearly 1 meter.

Engineers had to adjust the bridge design during construction to account for this shift.

The towers rise 283 meters (928 feet) above water, anchored by massive concrete piers.

The main cables are composed of 300,000 kilometers of wire strands, making them some of the strongest in the world.

The roadway is supported by a truss structure to ensure stability and reduce vibrations caused by wind and traffic.

7. Ponte Vecchio (Florence, Italy)

Type: Stone arch bridge

Construction Insights:

Built by Taddeo Gaddi and commissioned by the Medici family in the 14th century.

The bridge replaced an earlier wooden structure destroyed by floods.

Constructed using locally quarried stone to ensure durability.

The shops along the bridge added weight, but careful engineering has ensured the bridge’s longevity for centuries.

Survived World War II intact because German forces deliberately spared it during their retreat, making it one of Florence’s most cherished landmarks.

Good Job. Thank you.

LikeLike