Steel structures are widely used in modern construction due to their strength, flexibility, durability, and speed of construction. From industrial warehouses to high-rise buildings, steel provides an efficient solution for a variety of structural needs. For beginners, understanding the fundamentals of steel structure design is essential to ensure safety, compliance, and cost-effectiveness.

This guide provides a comprehensive introduction to steel structure design principles, components, load considerations, and best practices for 2026.

1. Introduction to Steel Structures

Steel structures are frameworks made from structural steel components, such as beams, columns, and braces. They support loads and provide stability for buildings, bridges, and other constructions.

Advantages of Steel Structures:

- High strength-to-weight ratio

- Flexibility for modifications and expansions

- Faster construction with prefabricated elements

- Resistance to environmental factors (fire, termites, decay)

- Recyclability and sustainability

Understanding these benefits helps engineers choose steel for appropriate applications.

2. Key Components of Steel Structures

A typical steel structure consists of the following main components:

2.1 Columns

- Vertical members that transfer loads from beams and floors to foundations

- Designed to resist axial loads, bending, and buckling

2.2 Beams

- Horizontal members supporting floors, roofs, or other loads

- Subject to bending, shear, and deflection

2.3 Bracing

- Provides lateral stability against wind, seismic forces, and torsion

- Can be diagonal, cross, or portal frames

2.4 Connections

- Bolted, welded, or riveted connections

- Critical for load transfer between components

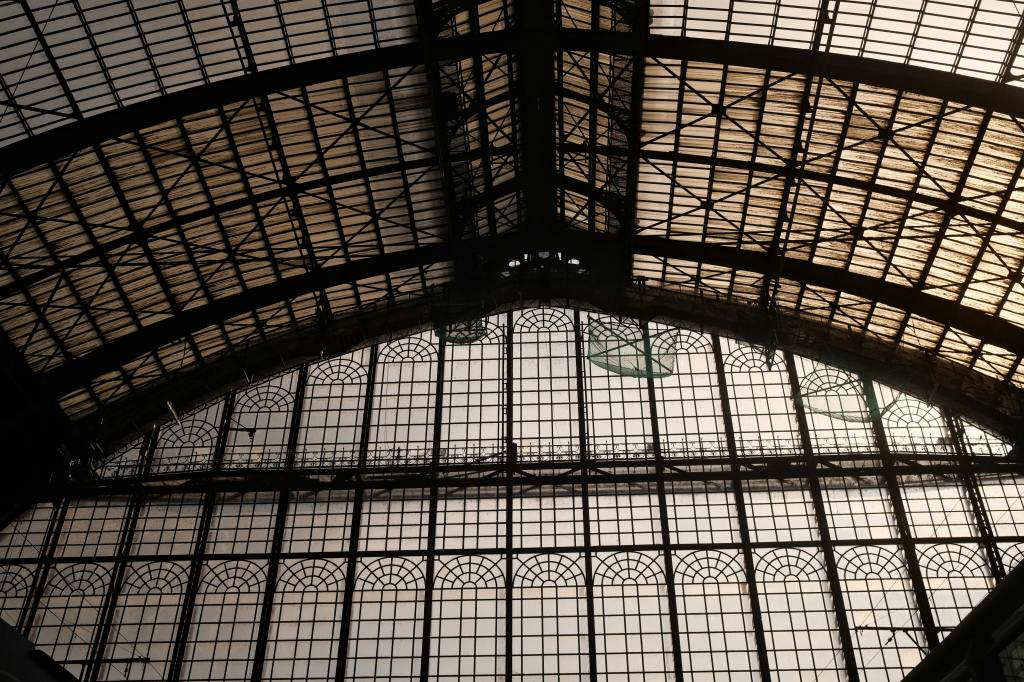

2.5 Roof and Floor Systems

- Roof trusses, purlins, and decking support loads and distribute them to the frame

Understanding each component is essential for efficient and safe structural design.

3. Load Considerations in Steel Structure Design

Loads are external forces that act on a structure. Proper load analysis ensures safety and durability.

3.1 Dead Loads

- Permanent loads from the structure itself (beams, floors, roof)

3.2 Live Loads

- Variable loads from occupants, furniture, equipment, or temporary storage

3.3 Environmental Loads

- Wind, snow, rain, seismic activity

3.4 Load Combinations

- Design codes require considering different load combinations to account for worst-case scenarios

- Example: Dead + Live + Wind or Dead + Live + Earthquake

Accurate load calculation is the foundation of a safe and optimized steel structure.

4. Design Principles and Codes

Steel structure design follows international and national building codes and standards, such as:

- AISC (American Institute of Steel Construction)

- Eurocode 3 (EN 1993)

- Turkish Standards (TS EN 1993)

Key Design Principles:

- Strength: Members must resist applied loads without failure

- Serviceability: Limits on deflection, vibration, and deformation

- Stability: Prevent buckling, sway, or collapse

- Durability: Resistance to corrosion, fire, and environmental factors

Designers must adhere to these principles for structural integrity and compliance.

5. Steps in Steel Structure Design

Step 1: Preliminary Design

- Determine span, column spacing, and structural layout

- Select preliminary member sizes based on experience or code tables

Step 2: Load Analysis

- Identify dead, live, and environmental loads

- Apply load combinations for worst-case scenarios

Step 3: Member Design

- Calculate bending, shear, axial, and torsional stresses

- Check member capacity against allowable limits

Step 4: Connection Design

- Design bolted, welded, or riveted connections to transfer forces safely

- Ensure ductility and redundancy

Step 5: Serviceability Checks

- Verify deflection limits and vibration criteria

- Adjust member sizes if necessary

Step 6: Final Design and Detailing

- Prepare detailed drawings for fabrication and erection

- Include member sizes, connection details, and material specifications

Following these steps ensures safe, efficient, and constructible steel structures.

6. Tips for Beginners in Steel Structure Design

- Start with simple projects and gradually progress to complex structures

- Familiarize yourself with design software like SAP2000, ETABS, or Staad.Pro

- Study design codes and manuals thoroughly

- Always consider constructability and site conditions

- Collaborate with experienced engineers and learn from real projects

Practical experience combined with theory is key to becoming proficient in steel design.

7. Common Mistakes to Avoid

- Underestimating environmental loads (wind, seismic)

- Ignoring connection design and detailing

- Overlooking lateral stability or bracing requirements

- Selecting inappropriate member sizes

- Neglecting fabrication and erection tolerances

Avoiding these mistakes improves safety, efficiency, and cost-effectiveness.

8. Tools and Technology for Steel Structure Design

Modern technology significantly improves design efficiency:

- SAP2000 / ETABS / Staad.Pro: Structural analysis and member design

- Tekla Structures: 3D modeling, fabrication, and detailing

- BIM (Building Information Modeling): Clash detection, coordination, and planning

- AI-assisted design tools: Optimize member selection and cost

Technology allows accurate, fast, and collaborative design processes.

Steel structure design is a fundamental skill for modern construction engineers. By understanding components, loads, design principles, codes, and software tools, beginners can design structures that are safe, durable, and efficient.

In 2026, steel structures remain a preferred choice for a wide range of projects, and mastering their design opens the door to career growth and successful project delivery.

Start with the basics, follow step-by-step procedures, leverage technology, and continuously learn from real projects to excel in steel structure design.

Leave a comment