What is Bored Pile in the Construction Industry and How to Use It?

Introduction

In the world of modern construction, foundations form the essential backbone of structural integrity. Among various foundation types, bored piles have emerged as a preferred choice for deep foundations, particularly in urban and high-load scenarios. This blog post delves into what bored piles are, their importance in the construction industry, and how to design and implement them effectively.

What is a Bored Pile?

A bored pile, also known as a drilled shaft or cast-in-situ pile, is a deep foundation formed by removing soil to create a cylindrical hole and then filling it with reinforced concrete. Unlike driven piles, which are hammered into the ground, bored piles are formed in place with minimal vibration and noise, making them suitable for urban environments or areas with strict noise restrictions.

Bored piles are typically circular in cross-section and can range in diameter from 300 mm to over 3000 mm. They can extend to depths exceeding 50 meters depending on soil conditions and structural requirements.

Applications of Bored Piles

Bored piles are used when shallow foundations are not feasible due to weak surface soils or when structures demand higher load-bearing capacities. Common applications include:

- High-rise buildings

- Bridges and flyovers

- Transmission towers

- Industrial complexes

- Retaining walls and diaphragm walls

Advantages of Bored Piles

- Low Noise and Vibration: Ideal for urban or sensitive sites.

- Customizable Diameter and Depth: Allows flexibility in design.

- High Load Capacity: Suitable for heavy structures.

- Minimal Displacement: Reduces soil heaving and ground movement.

- Adaptability to Varying Soil Conditions: Effective in clay, silt, sand, or mixed soils.

Disadvantages of Bored Piles

- Slower Construction Speed: Requires specialized equipment and procedures.

- Higher Initial Costs: More expensive compared to shallow foundations.

- Groundwater Complications: Water inflow can affect excavation.

- Quality Control Challenges: Hard to inspect after concreting.

Design Considerations

Designing a bored pile foundation involves geotechnical investigations, structural loading analysis, and pile-soil interaction studies.

1. Geotechnical Investigation

- Borehole logs

- Soil classification

- Standard Penetration Tests (SPT)

- Cone Penetration Tests (CPT)

- Groundwater table identification

2. Structural Load Analysis

- Vertical loads (dead + live loads)

- Lateral loads (wind, seismic)

- Moment and shear considerations

3. Pile Capacity Estimation

- End bearing capacity

- Skin friction resistance

- Settlement analysis

Design codes like Eurocode 7, AASHTO LRFD, or local standards guide the safe and efficient design of bored piles.

Installation Process

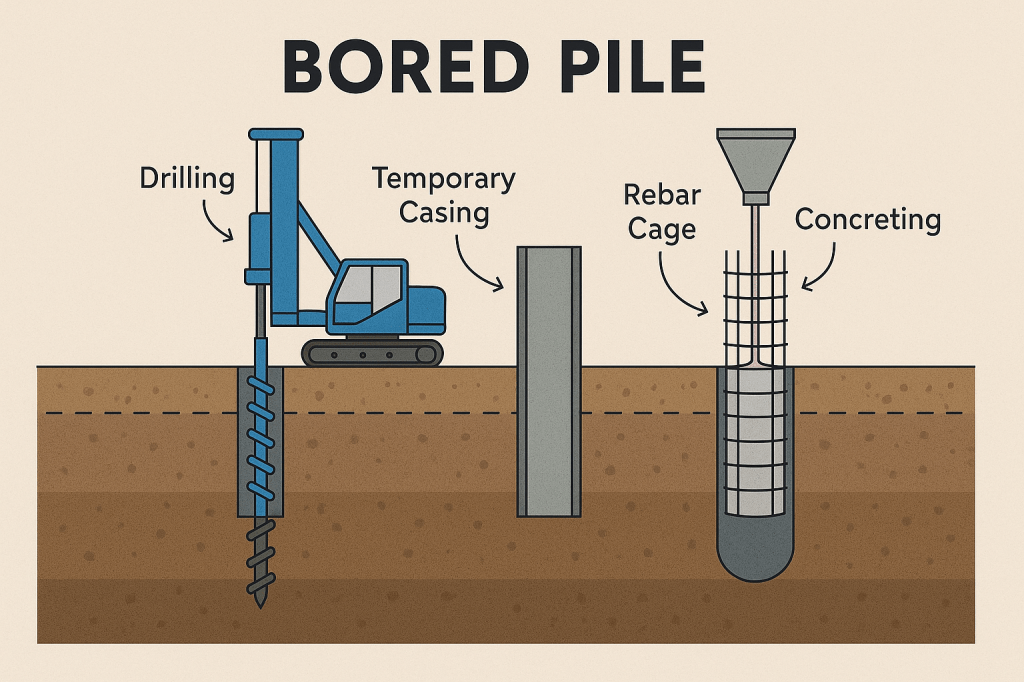

The process of bored pile installation includes several key steps:

1. Setting Out

Mark the exact locations and alignment of the piles based on the design drawings.

2. Drilling

Use a rotary drilling rig or auger to excavate the hole to the desired depth and diameter.

- Temporary casing or bentonite slurry may be used to stabilize the hole.

- Spoil is removed using buckets or augers.

3. Reinforcement Placement

Lower a prefabricated rebar cage into the hole. The cage is often suspended to avoid contact with the hole walls.

4. Concreting

Pour concrete into the hole using tremie pipes, especially if bentonite or groundwater is present. This prevents segregation and ensures quality.

5. Curing and Quality Control

Allow the concrete to cure and test for strength using methods such as:

- Cross-hole sonic logging

- Integrity testing

- Load testing

Equipment Used

- Rotary drilling rigs

- Kelly bar or continuous flight auger (CFA)

- Tremie pipes

- Temporary casings

- Bentonite/slurry mixing tanks

- Rebar cages and lifting cranes

Construction Challenges and Solutions

- Groundwater Ingress

- Solution: Use bentonite or polymer slurry for hole stabilization.

- Soft or Collapsible Soil

- Solution: Employ temporary casing or drilled shafts with liners.

- Rebar Cage Misalignment

- Solution: Use proper spacers and lifting mechanisms.

- Concrete Segregation

- Solution: Employ tremie concreting and maintain proper flow rates.

- Slurry Contamination

- Solution: Regularly monitor slurry properties (density, viscosity, sand content).

Case Study: High-Rise Building in Istanbul

For a 40-story building in central Istanbul, bored piles were selected due to soft clay layers in the upper 20 meters. Piles of 1200 mm diameter and 40 m depth were constructed using rotary rigs with bentonite support. Load testing confirmed adequate bearing capacity and settlement control.

Quality Assurance and Testing

- Pile Integrity Test (PIT)

- Low-Strain Dynamic Testing

- Static Load Testing

- Cross-Hole Sonic Logging

These tests ensure compliance with design and detect defects such as voids, necking, or honeycombing.

Cost and Time Considerations

- Cost Factors: Equipment rental, labor, concrete and steel prices, site accessibility.

- Time Factors: Curing periods, drilling rate, soil type.

Despite higher initial costs, bored piles often prove economical for long-term structural stability and safety.

Best Practices

- Always conduct a thorough geotechnical survey.

- Choose the appropriate slurry or casing based on soil conditions.

- Ensure proper alignment and cover of the rebar cage.

- Maintain concrete flow without interruptions.

- Follow international design codes and testing protocols.

Conclusion

Bored piles play a critical role in modern construction, providing the necessary strength and stability for complex and heavy structures. Their adaptability, low environmental impact, and ability to handle high loads make them indispensable for deep foundation systems. With proper design, equipment, and quality control, bored pile foundations ensure long-lasting and reliable structural support.

Whether you’re a civil engineer, contractor, or construction enthusiast, understanding the concept and application of bored piles is essential for navigating today’s complex construction challenges.

Leave a comment